POWER FOREVER, una empresa privada de alta tecnología reconocida a nivel nacional originaria de Shenzhen, se ha fundado en 2011, acumulando una vasta experiencia en la industria.En 2019, con el rápido crecimiento de nuestro negocio, respondimos a la invitación de inversión de Hefei,y decidimos trasladar nuestra sede a la ciudad natal del CEO, Hefei, registrándonos oficialmente como Hefei Power Forever Electronic Technology Co., Ltd.

En la actualidad, nuestra fábrica se encuentra en las plantas 5ª y 6ª del Edificio A2 del Parque Industrial Jiahai, en la Zona de Nuevo Desarrollo de Hefei, y ocupa una superficie de más de 4.000 metros cuadrados. Como una empresa dedicada a la investigación, desarrollo, producción y venta de cargadores de baterías y componentes electrónicos de potencia relacionados, Power Forever cuenta con un sistema de gestión integral y certificación de calidad ISO9001.

El equipo de I+D de Power Forever ha desarrollado una serie de cargadores profesionales y fiables adaptados a diferentes necesidades y aplicaciones. Ya sea para ambientes de baja temperatura de alta altitud, alta temperatura de alta humedad, o cargadores a prueba de polvo, a prueba de explosiones, a prueba de agua, y capacidades de buceo, podemos proporcionar las mejores soluciones para nuestros clientes. Nuestros cargadores a prueba de agua producidos profesionalmente y los cargadores montados en vehículos que van desde 100W a 7000W son ampliamente utilizados en diversos equipos eléctricos como carritos de golf, fregadoras de suelos eléctricas, motocicletas eléctricas, scooters eléctricos, vehículos eléctricos ligeros, coches eléctricos y carretillas elevadoras eléctricas.

Power Forever insiste en centrarse en el cliente, comprometiéndose a proporcionar productos y soluciones profesionales, fiables y rentables. Prometemos una calidad líder en el mundo, una garantía de reparación o sustitución de 2 años, así como precios más razonables y mejores servicios personalizados. Basándonos en este compromiso y en nuestra fuerza, hemos establecido con éxito asociaciones estables a largo plazo con clientes de más de 20 países.

Vídeo de empresa

Instalaciones de ensayo

Taller de fábrica

Proceso de integración de productos

Una vez finalizado el procesamiento, los trabajadores insertan manualmente los componentes de acuerdo con el programa de PCB, la placa de PCB se procesa mediante soldadura por ola y, a continuación, se vuelve a inspeccionar manualmente, se repara y se suelda, y se pasa la prueba de la máquina para garantizar que el PCBA está cualificado 100%.

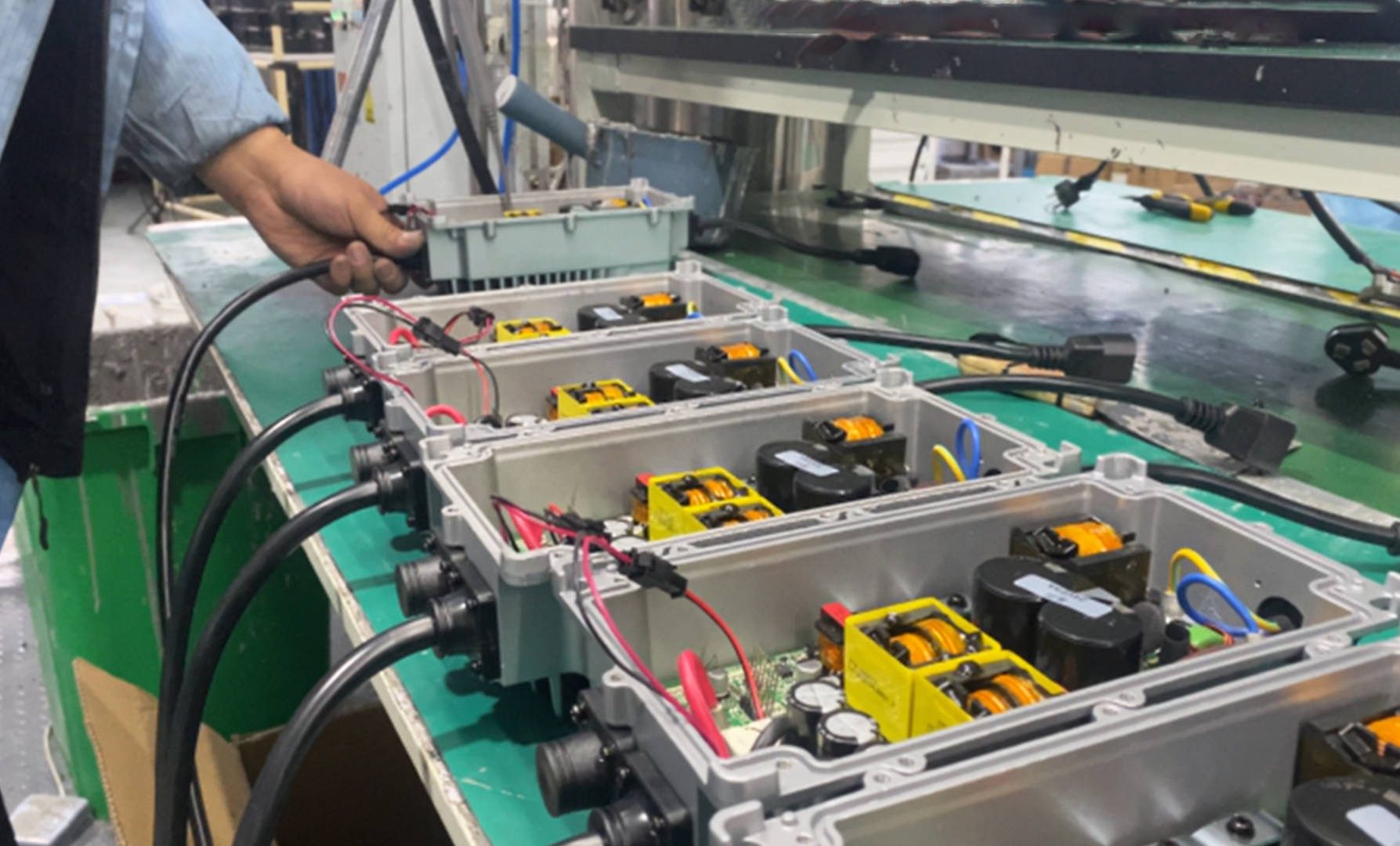

Línea de producción de montaje

Tras la prueba inicial, el PCBA y la carcasa de aluminio, así como los cables de entrada y salida, se ensamblarán según sea necesario y esperarán a la siguiente prueba.

Proceso de encolado

Una vez comprobado el cargador ensamblado, se pasa al siguiente paso de dispensación de cola y relleno de cola. El proceso de llenado de pegamento tiene las funciones de a prueba de polvo, a prueba de humedad y a prueba de agua, conducción de calor y resistencia al calor, y fijación para el cargador.

Proceso de prueba de rodaje

Una vez enfriado el cargador de cola, se pasa a la prueba de envejecimiento. Los trabajadores lo introducen en la máquina de envejecimiento y lo prueban según el tiempo establecido para garantizar un rendimiento estable y fiable. Las 7 máquinas de la fábrica pueden probar más de 1.000 cargadores al mismo tiempo para garantizar la eficacia de la entrega. El objetivo de la prueba de envejecimiento es evaluar la fiabilidad, estabilidad y seguridad del cargador durante mucho tiempo para garantizar una carga eficiente y segura.